Vertical lift modules are an amazing addition to any warehouse space. They help companies save valuable time, improve their efficiency, and even reduce the amount of needed storage space. Utilizing a VLM can also help improve safety in the workplace. Let’s take a closer look at what makes these pieces of equipment invaluable in your warehouse.

WHAT ARE VERTICAL LIFT MODULES?

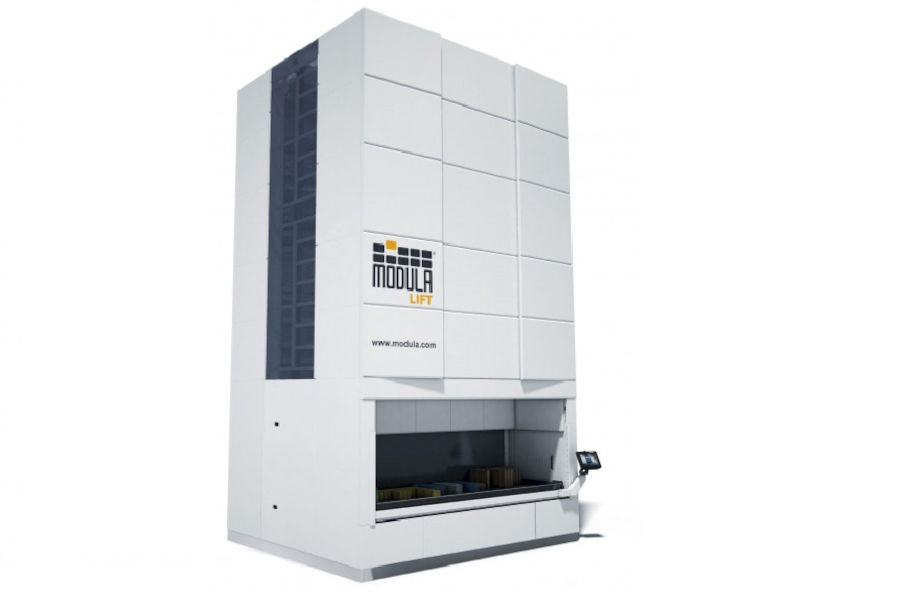

Vertical lift modules are devices that retrieve items from their storage tray and bring them to the employee. As would be expected based on the name, a VLM is a vertical tower that has two enclosed columns of trays inside.

The objective of a VLM is for it to find which tray has the needed product, select the product, and then transport that product to the employee. When functioning, an employee does not have to walk to retrieve anything; the machine brings the employee anything they need.

BENEFITS OF USING VERTICAL LIFT MODULES

Overview

Security and Tracking

Space-saving

Inventory Control

Time Saving

CONTACT DACO TO LEARN MORE ABOUT VERTICAL LIFT MODULES

For Your Facility DACO is an industry leader in warehouse products and services. Our sales team has over 200 combined years of experience. We know what questions to ask to determine your needs. Contact us today to learn more and follow us on Facebook to keep up to date with the latest news and updates.