VERTICAL LIFT MODULES

VERTICAL LIFT MODELS

VERTICAL LIFT MODULES – AUTOMATED STORAGE OF THE FUTURE

Vertical lift modules (VLMs) are vertical towers with two enclosed columns of trays, with an inserter/extractor located in the center of the system. Its job is to automatically locate and retrieve, from either the front or back of the system, the trays where the desired product or goods are stored, and deliver them to the operator who is waiting for them at the pick window.

These vertical lift modules eliminate the need for your employees to walk from one end of the facility to the other searching for what they need, thus increasing their productivity by up to 2/3rds. By taking advantage of your full ceiling height, they can be built up to 46’ high, and provide a secure, safe, and ergonomic work environment that will help your employees avoid unnecessary bending, reaching for parts, and walking everywhere.

VERTICAL STORAGE SOLUTIONS – SAVES YOU SPACE & TIME!

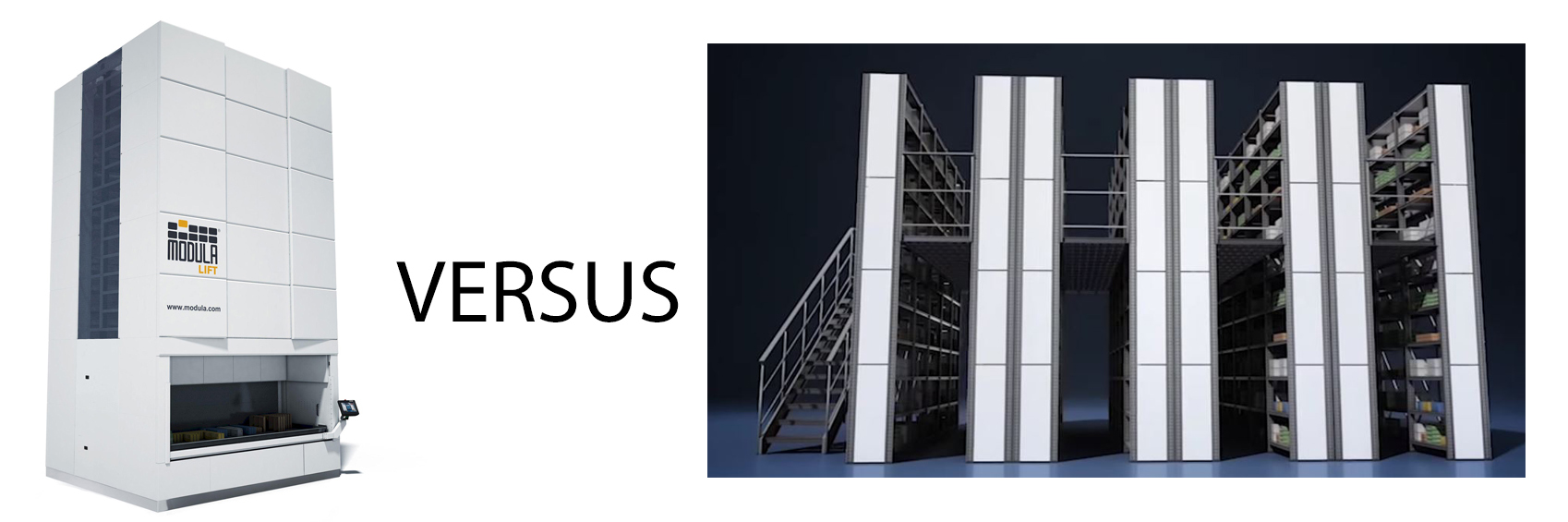

Companies underutilize the vertical space in their facilities, but VLMs are designed to take advantage of all the space between your floor and ceiling, building towers to store trays that optimize your full ceiling height. Up to 90% of floor space can be saved by installing vertical lift modules, over standard shelving units. This will eliminate the need for you to physically expand your building in order to create additional storage space.

These automated storage solutions come in many heights and widths, allowing you to create a system that fits your operational needs.

If you are wondering how VLMs can save you so much space, they do it by optimizing the storage cube. This makes the maximum amount of storage capacity that can be created, in the smallest footprint possible. Each tray is scanned, along with the height of the product on it, allowing the vertical lift module to automatically optimize the tray height. It can then store the product using the smallest amount of storage space possible, thus achieving maximum storage density.

BENEFITS OF VERTICAL LIFT MODULES (VLMS)

There are many ways that your company can benefit from Modula’s automated vertical lift modules including:

SPACE SAVING

TIME SAVINGS

PRODUCT SECURITY & TRACEABILITY

ERGONOMIC & SAFETY SOLUTIONS

BAY CONFIGURATIONS

ACCURACY & INVENTORY CONTROL

WAREHOUSE MANAGEMENT SOFTWARE (WMS)

DISCOVER WHETHER VERTICAL STORAGE IS RIGHT FOR YOUR COMPANY

Our systems experts can show you how vertical lift modules can save you space, reduce theft, and decrease labor costs. We look forward to discussing your needs and challenges, and coming up with a solution.

CONTACT US TODAY